- 1

- 2

- 3

Introduction

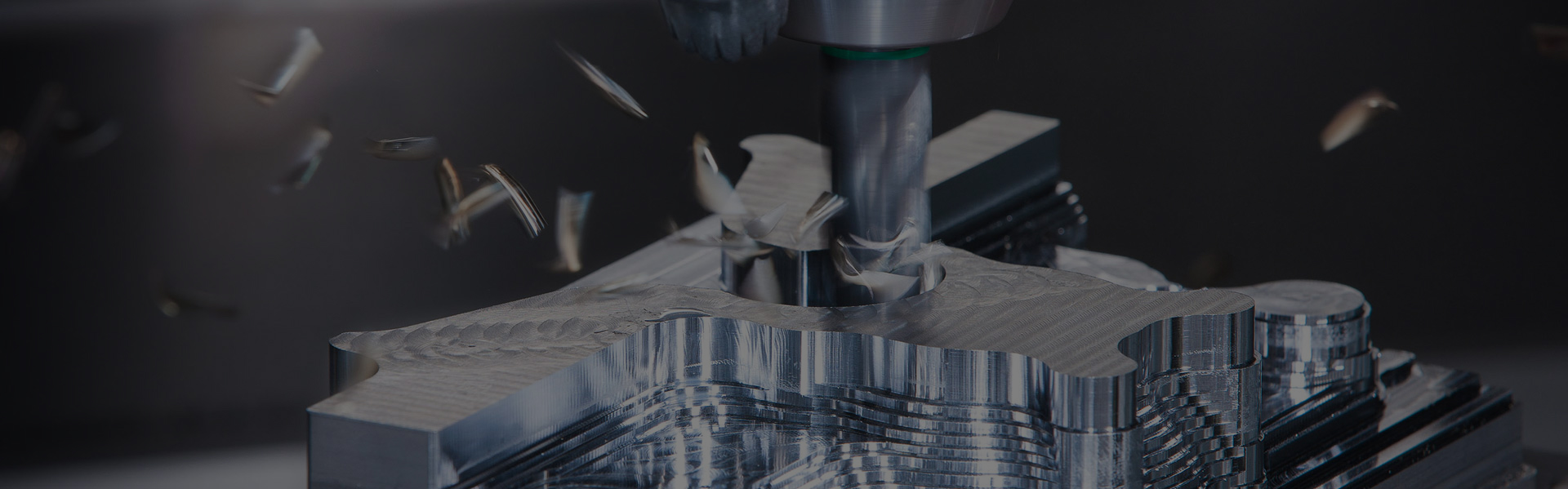

Julius - Globe Ltd. is a company located in Győrújbarát (in the middle between Vienna and Budapest), which has been founded in 1998. We work in two production hall of 1700 square meters. We are experienced in high precision CNC machining (milling, turning, grinding, wire eroding) for automotive, packaging, electronic, plastic, high-tech, medical, tobacco, railway, space, high-tech and press industry, moreover in planning and production of custom made jigs, machines, works stations mainly for automotive and space industry.

Our vision

Julius-Globe Ltd. is determined on offering at excellent quality, reliability, continuous and sustainable development to its partners. We do our best to meet the demands of our customers to the maximum extents of providing modern production equipment, state-of-the-art production technology, highly qualified colleagues and a cohesive, motivated team.

We intend to provide a fresh supplies continuously and sufficiently skilled and trained work force by means of professional re-training of our colleagues and involvement in the region’s vocational training.

It is important for us to pay special attention to and regularly promote social, cultural and charitable initiations.

Latest News

April 27, 2021

As we have already mentioned in our previous note, we have been manufacturing for the space industry for years. It is not always an easy task to present the whole spectrum of our production for the space industry, as the majority of the space industry projects are strictly confidential. Currently, we are still manufacturing parts for the space industry. In addition, in the framework of the development concept of the distributed space weather sensor system of the European Space Agency (ESA), we have developed a combined space radiation and magnetic field measuring instrument jointly with the researchers of Remred and the EC, by means of which the ESA will perform measurements in a mission of a constellation of small satellites intended for space weather measurements in the near future. The development of the instrument was accepted by the ESA, and the manufacture of the test copy will be started soon.

April 19, 2021

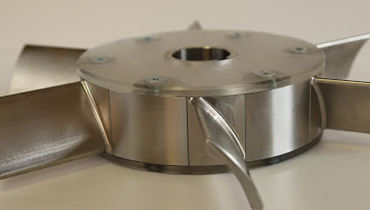

It’s time to give news also on the supply for a new industry. We came into contact with the national space industry already in December 2015. Since the beginning of 2018, we have made several products for the space industry. The first step was our involvement in mission RADCUBE 3U, in the framework of which we manufactured the whole mechanics of the RadMag radiometer for the Energy Science Research Centre for both the engineering development and the aviation units, then we made the frame structure of the Radcube satellite, the antenna opening unit and the related PCB holders for the C3S.

The RADCUBE 3U satellite was built in cooperation with the European Space Agency under management by C3S Kft. as a consortium, the scientific experiment within the useful cargo hold is coordinated by the Energy Science Research Centre. Though the project is managed by Hungarian specialists, many international participants are also involved in the consortium: the Polish Astronika and the International College of London from the United Kingdom have developed key parts of the device implementing the scientific experiment. Suppliers supporting the consortium also had a decisive role in the project, including the developers of the Spanish DHV making the solar panel and the colleagues of the Belgian KU Leuven making the stability control unit. Beyond the platform and the RadMag measuring instrument, a radiation tolerance experiment and a radio frequency experiment within a satellite will be also launched soon by the European Space Agency.

May 29, 2020

We are pleased to announce that this day we supplied 300 pieces of machined parts necessary for the ventilators to be used in intensive care units. We shall soon supply the parts also for the remaining 800 units. A company manufacturing medical devices, Celitron Medical Technologies Kft. has started the production of high-tech ventilators in response to the pandemic. In the framework of the project, 1100 ventilators will be soon assembled, which will serve the health of the Hungarian people, and may be used also for the ventilation of newborns, children and adults in intensive care units. We are grateful to our colleagues for their persistence in the difficult times. We are really happy and proud that our company would supply and our colleagues would manufacture the machined parts for these life-saving machines.